The world’s population is growing continuously and with it an insatiable hunger for meat. For many of us, it is an indispensable part of our diet. The traditional way of meat production exploits our nature, the animals, but also the people who work in slaughterhouses and reveals the cruel dark side of the burger sizzling on the grill. Can we never eat meat again without a guilty conscience, or could meat from the laboratory offer an environmentally friendly alternative that is still tasty?

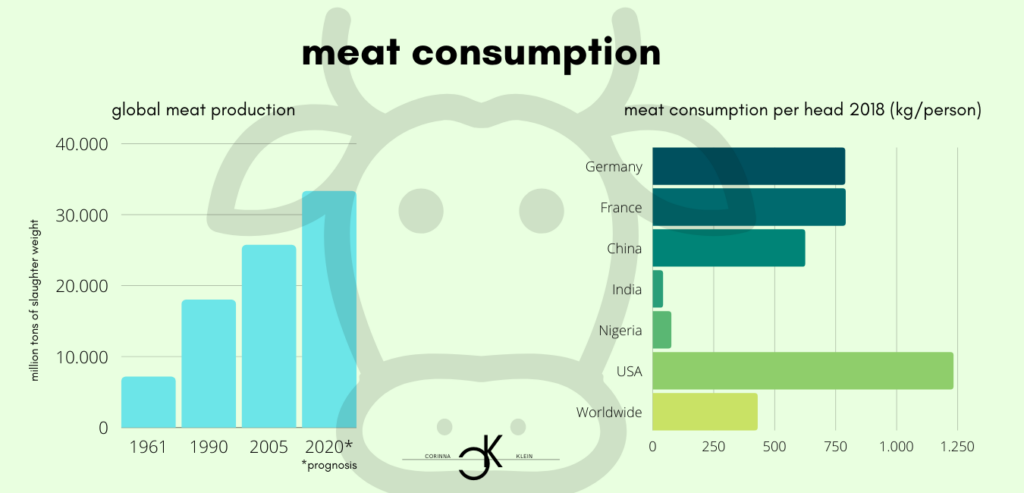

Our ravenous appetite for meat

The world’s population is expected to increase to nearly 10 billion by 2050 and to nearly 11 billion by 2100. The number of people is not the only reason for the ever-increasing demand for meat. More and more people benefit from the economic development and can afford to consume meat regularly, even daily. While in 1961 the global production of meat was 71.32 million tons of weight, it increased to 257.09 million tons in 2005 and reached 333 million tons in 2020 (forecast). This can also be seen in the annual per capita consumption of meat, which in 1990 was 33.5 kilograms per capita and in 2018 was already 42.9 kilograms per capita. This ravenous appetite for meat is leaving an increasingly dramatic mark on our planet.

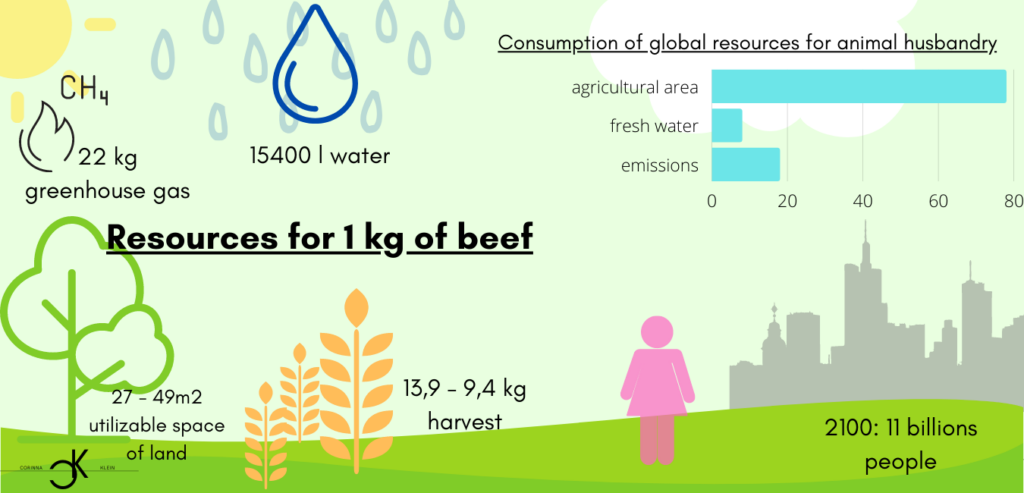

Animal agriculture, whether organic or conventional, now occupies 78% of the world’s available agricultural land, 8% of global freshwater and is responsible for 18% of global greenhouse gas emissions. It fuels deforestation, the reduction of biodiversity and, due to the large use of antibiotics, is a breeding ground for multi-resistant germs. There are also ethical aspects, as conventional animal husbandry is often associated with immense suffering of the animals and stressful working conditions for the employees in slaughterhouses.

Is there hope for the breakfast bacon?

In 2013, news spread that lab-grown meat, was used to make a hamburger. Meanwhile, a large number of start-ups around the world are researching the possibility of producing clean meat from the laboratory, as well as economic production methods for industrial use. This approach offers several advantages. For example, it would be possible to grow only the tissue and cells that are actually needed. The slaughter yield of cattle is between 50 – 60%, which means that about half of the animal is thrown away (hair, offal, hooves, etc.). In addition, biotechnologically produced meat is easier to produce without the massive use of antibiotics. The stressful situation in conventional slaughterhouses would also be eliminated. Positive effects can be seen in the elimination of transport routes, reduced water consumption, elimination of methane and the problem of disposal of animal waste. In addition, production can be carried out according to demand and takes much less time than, for example, raising cattle. Research has changed in recent years, and since December 2020, even one product has been approved for sale in Singapore. Have we solved the problem of world hunger and how do you even grow meat from the lab?

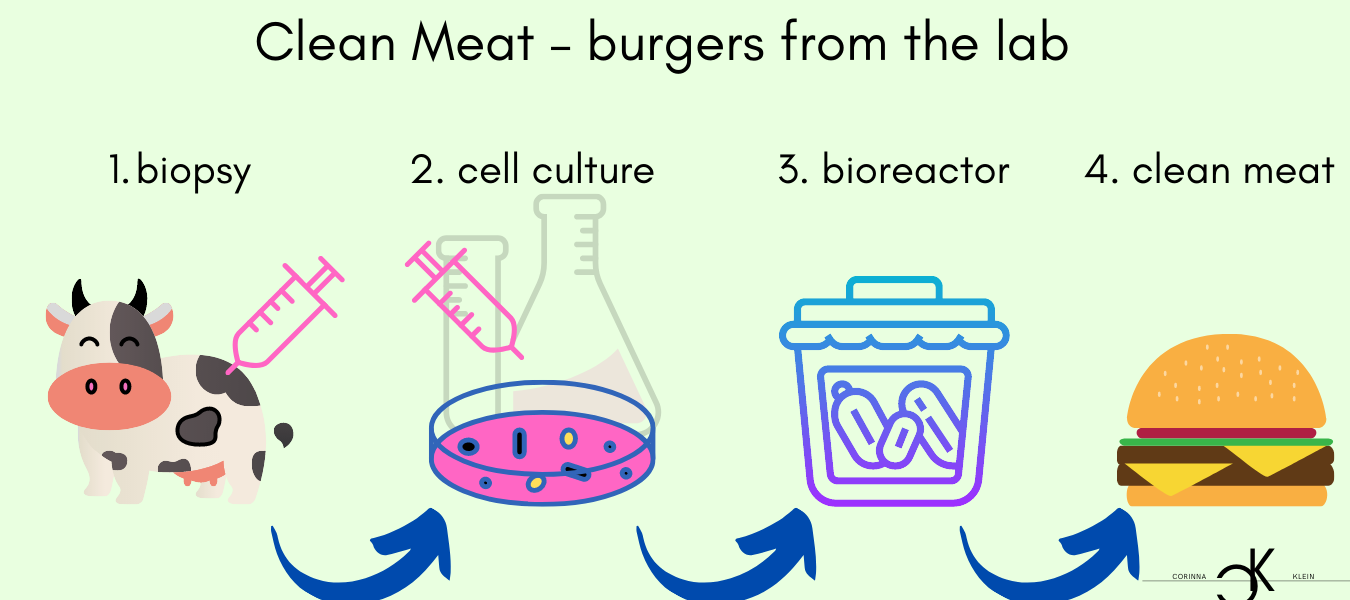

How does a lab-burger grow?

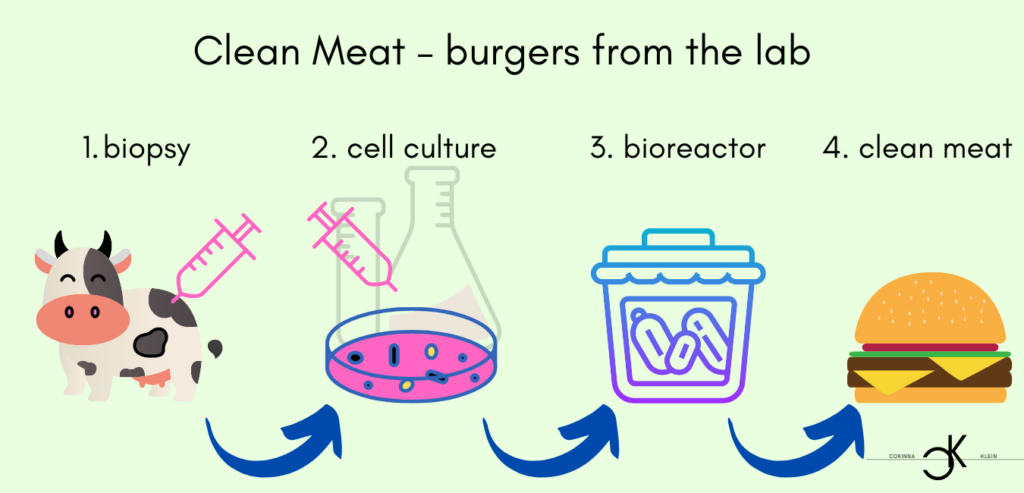

The technology on which the clean meat approach is based has already been in use for some time. It is the basis for the culture of human skin cells, which are used as transplants for burn victims. To obtain the required cells, a biopsy is taken from the animal. The animal does not have to die for this and the removal is almost painless. In order to avoid having to take a biopsy every time, pluripotent stem cells are used, from which muscle cells subsequently differentiate and grow. In the future, cell banks could be established so that no or very few biopsies need to be taken from living animals. There are now various techniques and methods for growing and cultivating the cells. It usually goes something like this:

The muscle cells created from stem cells are placed in a nutrient solution in which they divide and multiply. Normal muscle cells with the expression of muscle fibres are formed, as would also happen in animals. Thus, a large amount of muscle meat can be grown from a relatively small amount of sample. The cultures are then transferred to bioreactors. These are large vessels made of stainless steel in which an optimal environment can be created by imitating the conditions present in the animal. The temperature is controlled as well as the supply of oxygen and nutrients. Waste products are removed from the system. As the system is constantly monitored and isolated from the outside world, the use of antibiotics can be largely dispensed with. In some cases, the use of electrical impulses, which mimic the electrical stimulation of muscle cells by nerve cells, produces structures similar to those of a living animal. Subsequently, fat cells are added, also grown in the laboratory, which are also a component of conventionally produced meat (conventional meat may also contain connective tissue, blood vessels and bones). For this reason, so far rather thinly layered, so-called unstructured meat is produced, which is best processed into minced meat. However, the resulting meat is definitely ‚real‘ meat, which is at least as healthy as conventional meat. The production of steaks and fillets will be more challenging, as this would require growing structured meat in a stable cell network, which is supplied via channels and constantly trained.

Does that save the future?

There is still a long way to go before market-ready products are approved worldwide and their mass production is competitive and cost-effective. Governments and companies worldwide must accompany and support this process (regulatory framework for approval, investment in research and production, etc.). Important steps have been taken, first approvals already exist and more and more companies & governments recognize the need and get involved. Still, the product is not completely animal-free. For the extraction of the stem cells, some animals would still have to be kept, which would have to undergo a biopsy again and again. In contrast to conventional animal husbandry, however, there would be both significantly fewer animals and they would have to endure significantly less strain. Moreover, these animals could be kept in a more species-appropriate manner. Breeding in the laboratory also makes use of products that are partly of animal origin. Thus, millions of fetuses still die every year for the production of sera, which are an indispensable ingredient for the cultivation of cells. Here, too, plant-based nutrient media are now available. Moreover, it is by no means the case that no energy is required for the mass production of laboratory meat. Various projections and models exist for determining greenhouse gases. Some say it takes 2.5 kilograms of nutrients from plant sources to produce one kilogram of lab-grown beef, compared to 10 – 14 kilograms of grains needed to produce one kilogram of beef. Other models predict a similar consumption of resources as for conventional meat.

Well then?

Lab meat is definitely real meat and, in the future, probably a competitive product to conventional meat. It remains to be seen how well consumers will accept the meat. It should not be forgotten that the healthiest thing for people and also for the environment is simply to eat a little less meat.